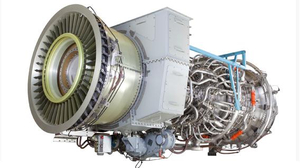

The PGT25 family of gas turbines draws its high efficiency and light weight from GE’s aeroderivative technologies proven in energy applications and aircraft engines, while its ruggedness is inherited from our heavy-duty gas turbine designs. Evolution from the proven GE Oil & Gas models has ensured high reliability and availability for the unique demands of this industry.

PGT25

The PGT25 is a simple cycle, two shaft gas turbine consisting of an LM2500 aero derivative gas generator coupled with a rugged, industrial power turbine. It leverages the best GE Oil & Gas technology to respond to the demands of a gas turbine in the 23 MW range with high efficiency, reliability and availability, and low environmental impact. PGT25 can operate on a large range of both liquid and gas fuels. It is assembled on a rigid, lightweight base plate with extensive use of standard components, preassembled and tested in the shop to minimize on-site assembly time. Easy maintainability is one of the main features: the gas generator and low pressure turbine (cartridge) can both be easily and quickly removed and replaced, in order to minimize downtime.

PGT25+

The PGT25+ gas turbine was developed for 30 MW ISO shaft power service with the highest thermal efficiency level (approx. 41%). Its LM2500+ gas generator (updated version of the LM2500 various technology enhancements include a zero stage added to the axial compressor) is coupled with a 6,100 RPM, two-stage, high-speed power turbine. The LM2500+ is designed for ease of maintenance, high availability, reliability and efficiency. Specialized aeroderivative annular combustion chamber fuel nozzles make the PGT25+ ideal for a wide range of mechanical drive (gas pipeline, etc.), power generation, industrial cogeneration, and offshore platform uses in any environment. Engineering simplicity and advanced materials yield long times between overhauls and lower maintenance costs.

PGT25+G4

The gas generator is based on the LM2500+ design with enhancements to increase flow and temperature capabilities. The 6,100 RPM power turbine, from our proven PGT25+, is capable of direct coupling to the driven equipment for simplicity and improved efficiency and maintenance. The annular combustor is from the LM2500+ with modifications to enable higher firing temperature, reduce maintenance cycle time, and keep NOx at LM2500+ levels even at higher firing temperatures. The enhanced PGT25+G4 package is a modular solution for improved integration of auxiliaries, reduced installation and commissioning time, and easy maintainability. Upgrade kits are also available for the installed base of PGT25+ units to increase output power by 10%.

The information in this webpage is wrong or out-of-date? Please contact info(at)etn.global