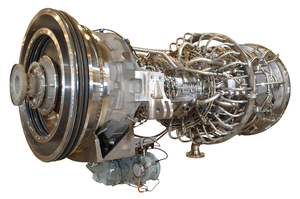

This powerful machine represents the most extensive collaboration of design and manufacturing expertise in the history of GE drawing proven design advantages from GE Aviation’s CF6-80C2/80E and GE Energy’s Frame 6FA+e gas turbine. This simple-cycle, three-shaft gas turbine uses intercooling technology to increase power and efficiency. At more than 100 MW or 134,000 shaft horsepower and 46% efficiency, the LMS100 provides the highest level of performance of any aeroderivative gas turbine.

Its aeroderivative core and free power turbine allow operating flexibility not seen in other gas turbines of its size. The free power turbine is ideal for mechanical drive applications due to the simple change-out of the first stage nozzle to optimize performance for 3,000 or 3,600 rpm drive shaft speeds and is capable to operate over a wide range of speeds. Its partial speed efficiency and ability to maintain power and efficiency at higher ambient temperatures is also better than other gas turbines in its class. The modular design and ability to change-out the supercore (core + intermediate pressure turbine assembly) engine in 24 hours, provides increased availability. The LMS100 utilizes a single design for 50Hz, 60Hz and mechanical drive with one common gas turbine, which improves fleet reliability.

The information in this webpage is wrong or out-of-date? Please contact info(at)etn.global