H2-IGCC

The H2-IGCC project, co-funded by the European Union’s 7th Framework Programme for Research and Development, is based on the initiative outlined in the European Turbine Network’s (ETN) Position Paper on Gas Turbine Fuel Flexibility (August 2007).

In November 2009 the H2-IGCC project kicked off with 24 partners from 10 countries with a total budget of 17,8 million euro. Successful dissemination and implementation of the project results will be an important step towards opening up the market for Integrated Gasification Combined Cycle (IGCC) with Carbon Capture and Storage (CCS) by 2020, by increasing gas turbine efficiency and fuel flexibility.

LOW EMISSION GAS TURBINE TECHNOLOGY

FOR HYDROGEN-RICH SYNGAS

FP7-ENERGY-2008-TREN-1

ENERGY 6.1.4:

ADVANCED GAS TURBINES FOR SOLID FUEL GASIFICATION PROCESSES

Acronym: H2-IGCC

Acronym: H2-IGCC

Collaborative Project: FP7-239349

Duration: 4.5 years (2009-2014)

Budget: 17.8 M Euro (11.3 M Euro EU funding)

Co-funded by the European Commission, Directorate-General for Energy

OBJECTIVE

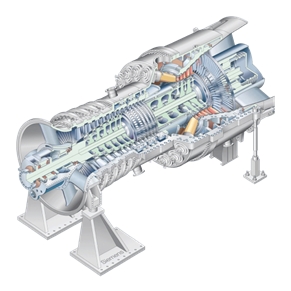

The overall objective of the H2-IGCC project is to provide and demonstrate technical solutions which will allow the use of state-of-the-art highly efficient, reliable gas turbines (GTs) in the next generation of Integrated Gasification Combined Cycle (IGCC) plants. The goal is to enable combustion of undiluted hydrogen-rich syngas with low NOx emissions and also allowing for high fuel flexibility. The challenge is to operate a stable and controllable GT on hydrogen-rich syngas with emissions and processes similar to current state-of-the-art natural GT engines. The H2-IGCC project aims to tackle this challenge as well as fuel flexibility, by enabling the burning of back-up fuels, such as natural gas, without adversely affecting the reliability and availability.

VISION

TO PAVE THE WAY FOR COMMERCIAL DEPLOYMENT OF EFFICIENT, CLEAN, FLEXIBLE AND RELIABLE IGCC PLANTS WITH CCS BY 2020

In March 2007 the European Council concluded that the 20% CO2 reduction targets by 2020 are not achievable without carbon capture and storage (CCS), the only technology available to mitigate emissions from large-scale fossil fuel usage. CCS is also endorsed by the European Commission’s Strategic Energy Technology Plan (SET-Plan) as a vital technology to reach the emission reduction goals and to build a low carbon economy with reduced dependence on external fuel supply.

The target year of 2020 for CCS deployment is only achievable if different parts of the efficiency chain are improved in building near zero emission power plants. The technology for the next generation of IGCC plants with CCS is promising but still requires development and demonstration of hydrogen GT technology as well as overall process integration. This process integration approach used in the H2-IGCC project will enhance confidence and significantly reduce deployment times for new technologies and concepts developed in this project.

Over the past decade, a number of initiatives on clean coal technology and IGCC have started around the world. Successful mitigation of climate change requires global efforts. Therefore, international knowledge sharing is essential to significantly reduce the time and the cost of bringing CCS to the market. Research findings and results of the H2-IGCC project will be publicly disseminated at international conferences and on this website.

Over the past decade, a number of initiatives on clean coal technology and IGCC have started around the world. Successful mitigation of climate change requires global efforts. Therefore, international knowledge sharing is essential to significantly reduce the time and the cost of bringing CCS to the market. Research findings and results of the H2-IGCC project will be publicly disseminated at international conferences and on this website.

The H2-IGCC project brings together 24 partners from industry and academia with the common goal to increase gas turbine efficiency and fuel flexibility without affecting the reliability and availability in a pre-combustion IGCC-CCS plant configuration. A successful outcome of this project will be an important step towards opening up the market for a commercial implementation of IGCC-CCS technology.

In order for industry to invest in the next generation of IGCC plants with CO2 capture systems, both technical and commercial risks need to be quantified and minimized, specifically those associated with the gas turbine. Enabling combustion of undiluted syngas derived from coal in advanced gas turbines will enhance the conversion efficiency, which in turn will partly compensate the efficiency loss occurred during the CCS process.

H2-IGCC Consortium Members |

|

CoordinatorUtilitiesE.ON Engineering OEM’sSuppliers / Service providers |

Research Institutes / UniversitiesDLR |

STRUCTURE

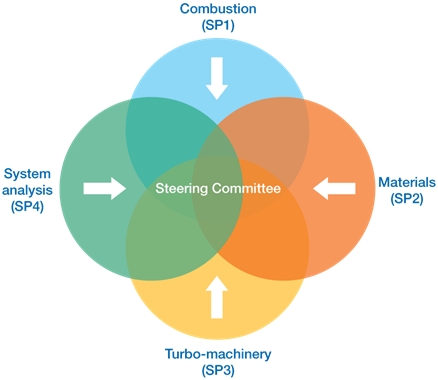

The technical challenges being addressed by the H2-IGCC project are divided into 4 Subprojects (SP):

SUBPROJECTS

COMBUSTION (SP1) – Safe and low emission combustion technology for undiluted, hydrogen-rich syngas will be developed and demonstrated. In order to achieve this, problems resulting from the differences in combustion properties of hydrogen and natural gas need to be addressed and solved. These are higher flame speed, higher adiabatic flame temperature, drastically reduced auto-ignition delay times and the large increase in volumetric fuel flow rate of hydrogen compared to natural gas.

MATERIALS (SP2) – Improved Materials Systems with advanced coatings able to protect hot path components base materials against different temperatures and compositions of exhaust gases will be delivered. Cost-effective materials and coatings technologies will be developed to overcome the component life-limiting problems of overheating and of hot corrosion resulting from the higher temperatures and residual contaminants in the syngas, including validation of materials performance data, life prediction and monitoring methods. Simulation tools for estimating performance and lifetime of materials systems will also be enhanced to suit the new operating environments.

TURBOMACHINERY (SP3) – Modified compressor, turbine and turbine cooling designs will be delivered. Compressor stable operation should enable the switch between fuels without compromising efficiency with the increased fuel mass flow rate that could lead to compressor instability. Turbine design has to cope with a different enthalpy drop, while the turbine cooling system has to cope with the higher specific heat of the exhaust gases. This will result in increased operating temperatures of the components in comparison with natural gas-fired gas turbines. Potential turbine vibration problems will also be addressed.

SYSTEM ANALYSIS (SP4) – System analysis will evaluate the optimum IGCC plant configurations and set up guidelines for optimised full scale integration providing a detailed system analysis that generates realistic techno-economical results for future gas turbine based IGCC plants with CCS. In particular, the compatibility of the combustion technology with the materials and turbo-machinery requirements will be optimised.

For further information, please contact the Project Coordinator:

|

Christer Bjorkqvist, Managing Director, ETN (H2-IGCC Project Coordinator) Ugo Simeoni, Technical Project Coordinator, ETNEuropean Turbine Network (ETN) Chaussee de Charleroi 146-148/20 1060 Brussels, BelgiumTel: +32 (0)2 646 15 77E-mail: info (at) etn.global Website: www.etn.global |